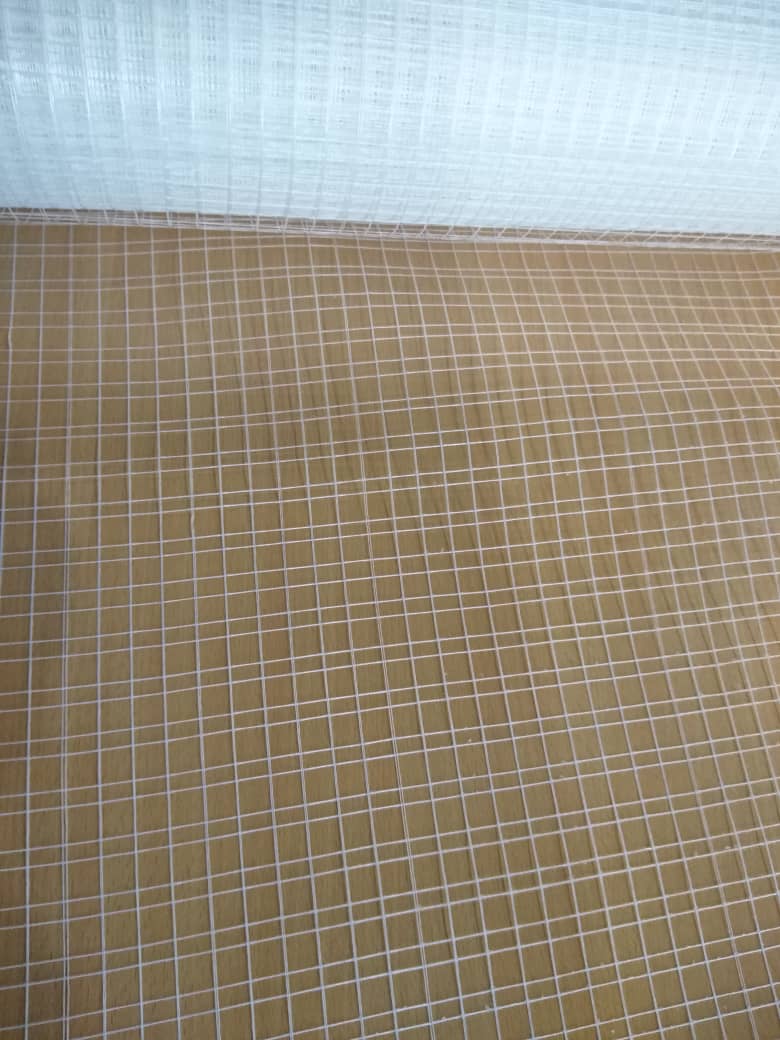

Fiberglass Scrim with Flame Retardant

laid scrim looks like a grid or lattice. It is made from continuous filament products (yarns). In order to keep the yarns in the desired right-angled position it is necessary to join these yarns together. In contrast to woven roducts the fixation of the warp and weft yarns in laid scrims must be done by chemical bonding. weft yarns are simply laid across a bottom This is achieved through a manufacturing process.

Generally laid scrims are about 20 – 40 % thinner than woven products made from the same yarn and with an identical construction.

Many European standards require for roofing membranes a minimum material coverage on both sides of the scrim. Laid scrims help to produce thinner products without having to accept decreased technical values. It is possible to save more than 20 % of raw materials such as PVC or PO.

Only scrims permit production of a very thin symmetrical three layer roofing membrane (1.2 mm) that is often used in Central Europe. Fabrics cannot be used for roofing membranes that are thinner than 1.5 mm.

The structure of a laid scrim is less visible in the final product than the structure of woven materials. This results in a smoother and moreeven surface of the final product.

The smoother surface of final products containing laid scrims allows to weld or glue layers of the final products more easily and durably with each other.

The smoother surfaces will resist soiling longer and more persistently.

The use of glassfibre scrim reinforced nonwovens per-mits higher machine speeds for the production of bitu-men roof sheets. Time and labour intensive tears in the bitumen roof sheet plant can therefore be prevented.

The mechanical values of bitumen roof sheets are sub-stantially improved by scrims.

Materials that tend to tear easily, such as paper, foil or films from different plastics, will be prevented from tearing effectively by laminating these with laid scrims.

Whilst woven products may be supplied loomstate, a laid scrim will always be impregnated. Due to this fact we have an extensive knowledge in respect to which binder may be best suited to different applications. The choice of the right adhesive may enhance the bonding of the laid scrim with the final product considerably.

The fact that the upper and lower warp in laid scrims will always be on the same side of the weft yarns guarantees that the warp yarns will always be under tension. Therefore tensile powers in warp direction will be absorbed immediately. Due to this effect, laid scrims often show a strongly reduced elongation.When laminating a scrim between two layers of film or other materials, less adhesive will be needed and the cohesion of the laminate will be improved.The production of scrims always requires a thermal drying process. This leads to preshrinking of the polyester and other thermoplastic yarns which will improve substantially subsequent treatments done by the customer.

If you have any inquiries for all regular laid scrims and fiberglass products, such as

polyester scrim with PVOH binder,

polyester scrim with PVC binder,

fiberglass scrim with PVOH binder,

fiberglass scrim with PVC binder,

Welcome to contact us, any time!