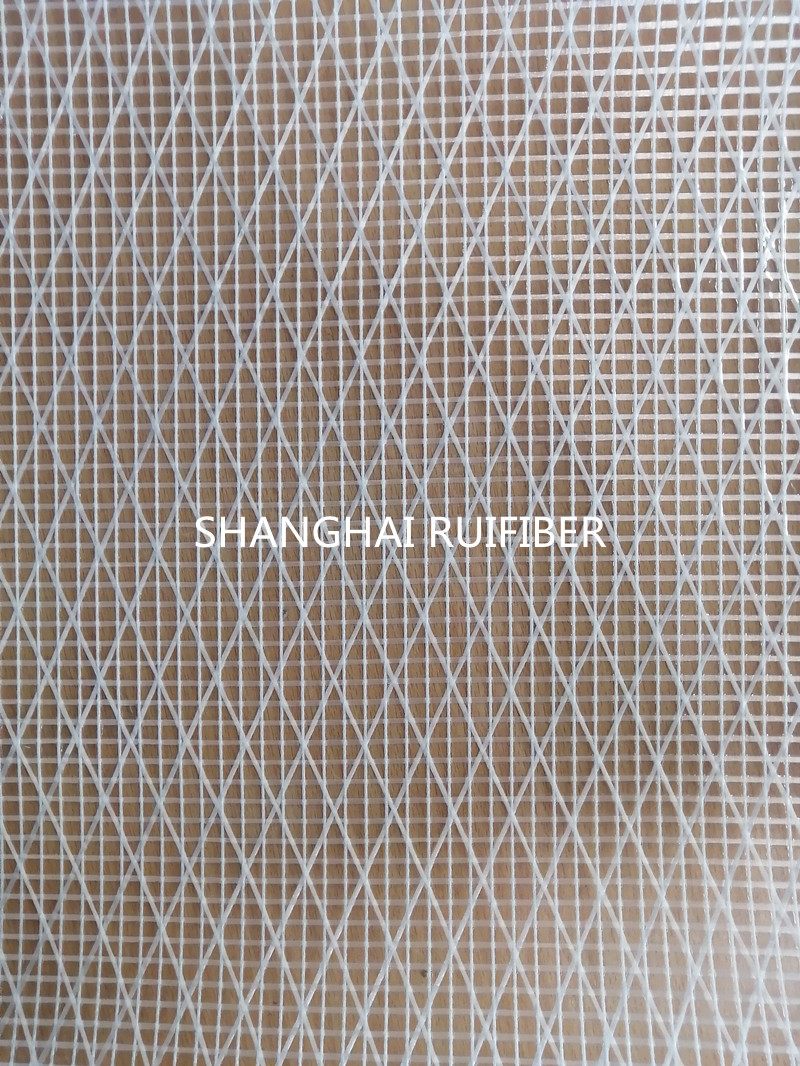

Laid Scrim, as thin as a cicada wing.

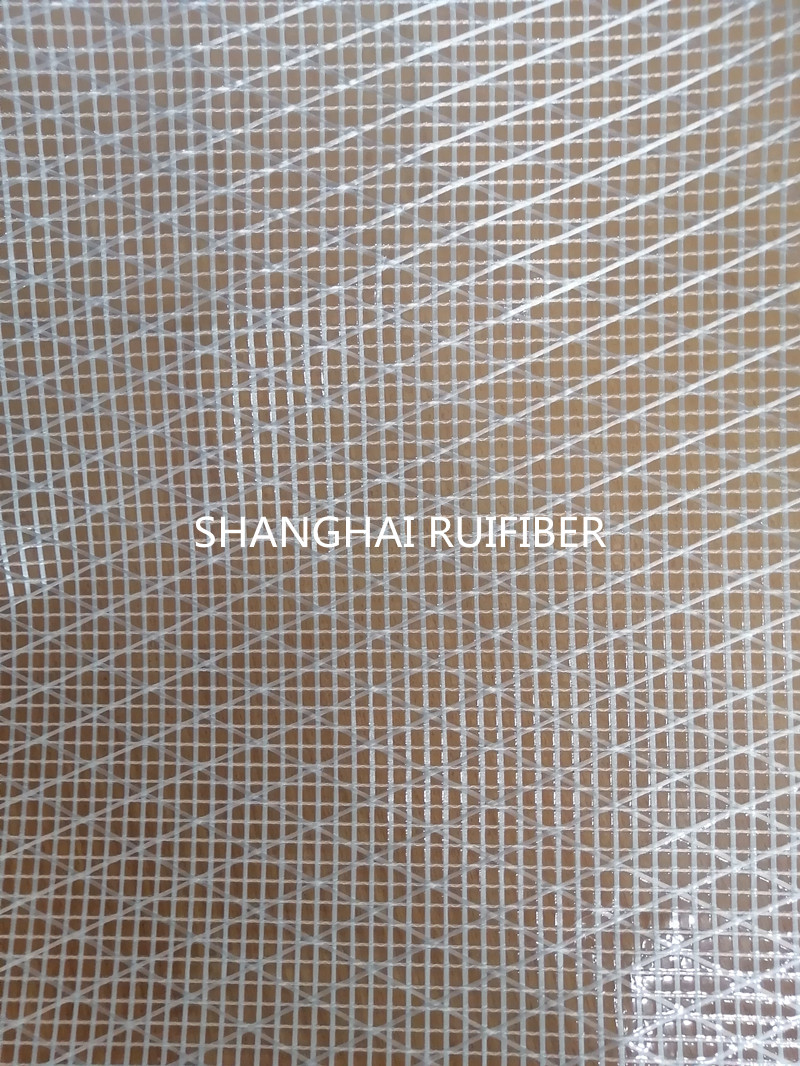

Recently we got inquiry from customers about thickness of laid scrim.

Here we are measuring the thickness of laid scrim.

The quality of Laid Scrim is not determined by thickness, usually weight and glue affect much.

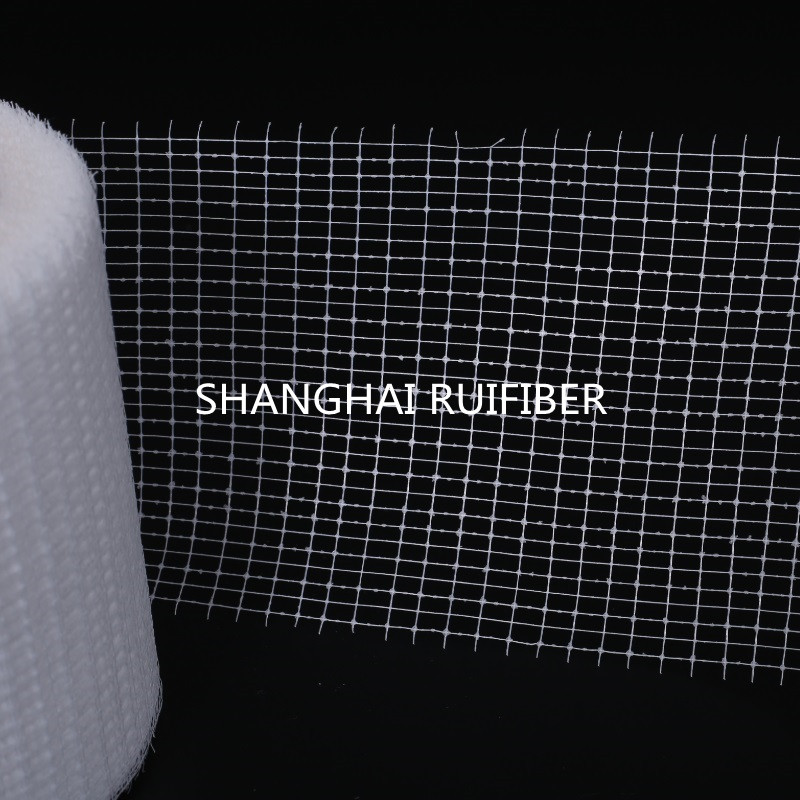

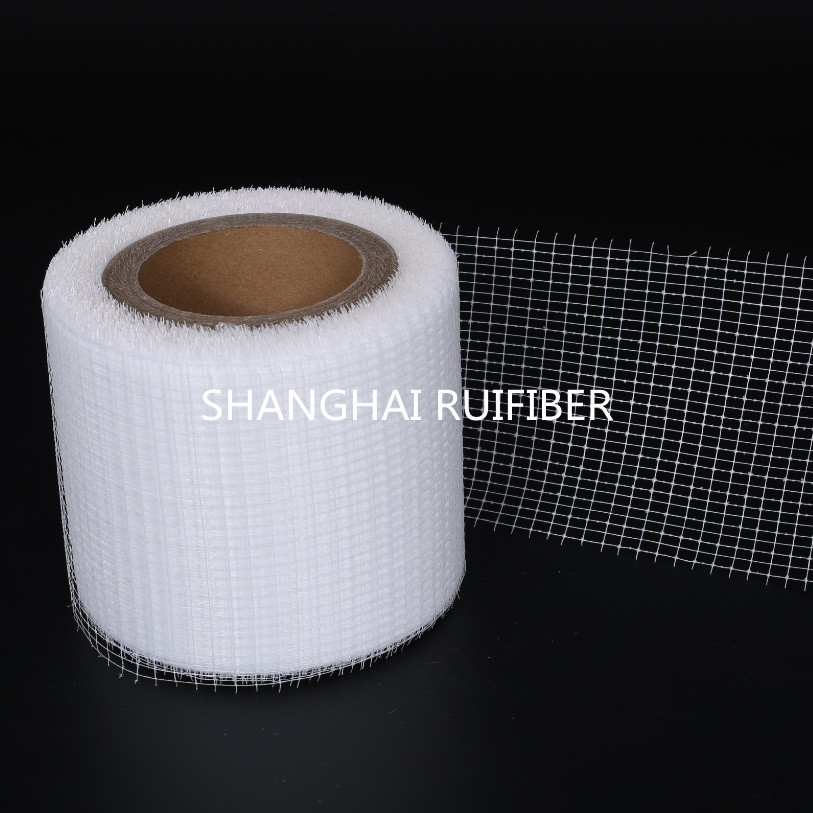

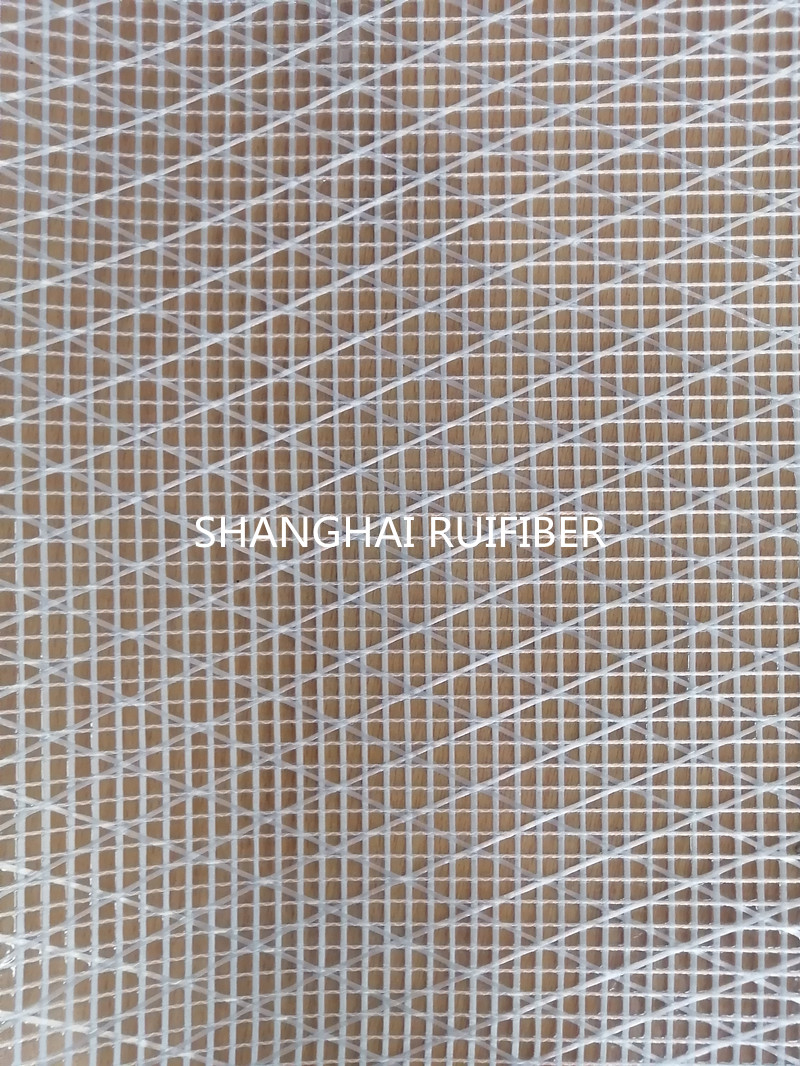

A laid scrim looks like a grid or lattice. It is a cost-effective reinforcing fabric made from continuous filament yarn in an open mesh construction. The laid scrim manufacturing process chemically bonds non-woven yarns together, enhancing the scrim with unique characteristics.

The color of the fabric can be customized according to the customer’s requirements, and the use of dyed yarn in warp or weft is also applicable. Yarn varieties available for making non-woven (tiled) mesh fabrics include:

High tenacity, Flexible, Tensile strength, Low shrinkage, Low elongation, Fire-proof Flame retardant,Waterproof,Corrosionresistant,Heat-sealable,Self-adhesive,Epoxy-resin friendly, Decomposable, Recyclable etc.

Laid scrim is very light, the minimum weight can be 3-4 grams only, this saves the large percent of raw material.

Application:

Building

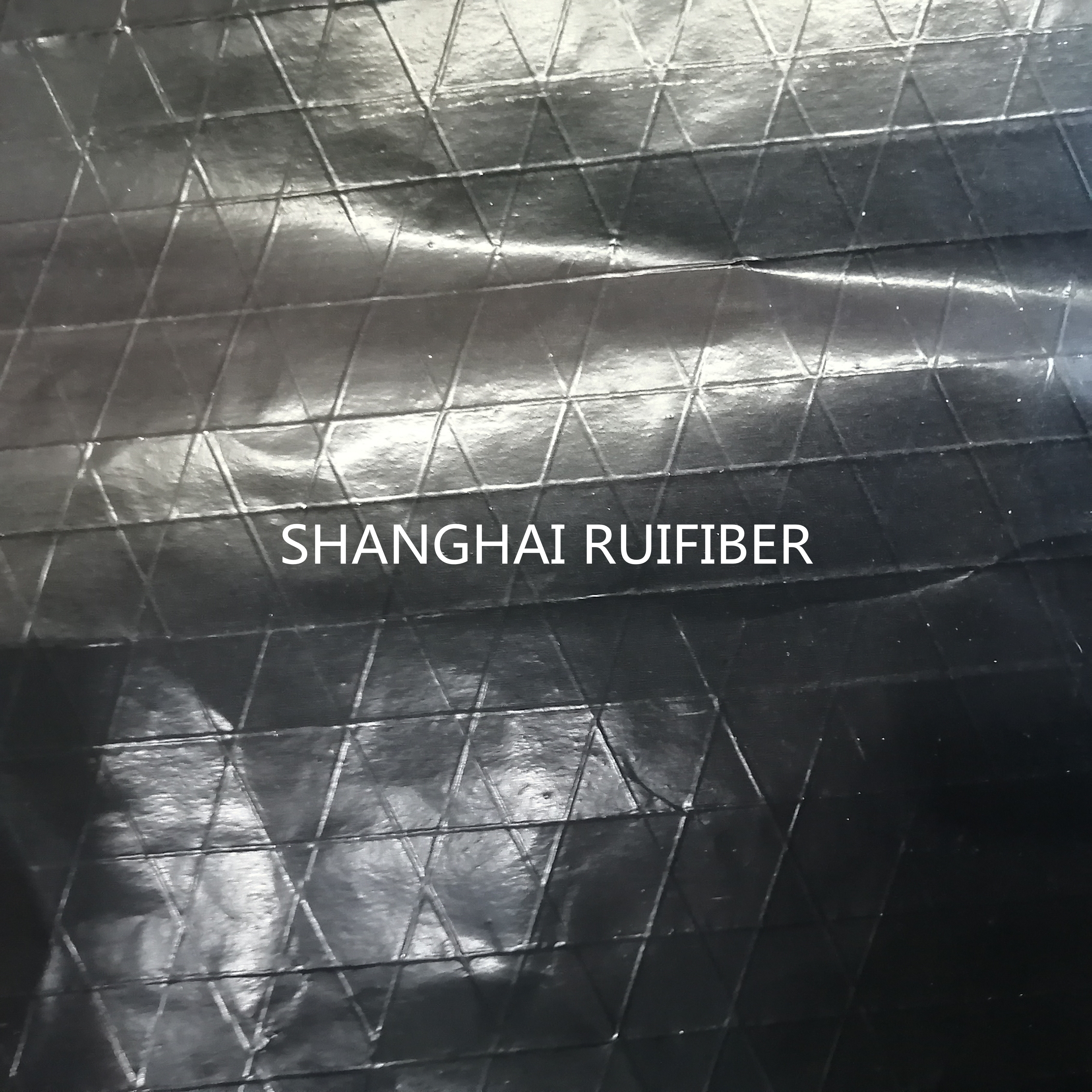

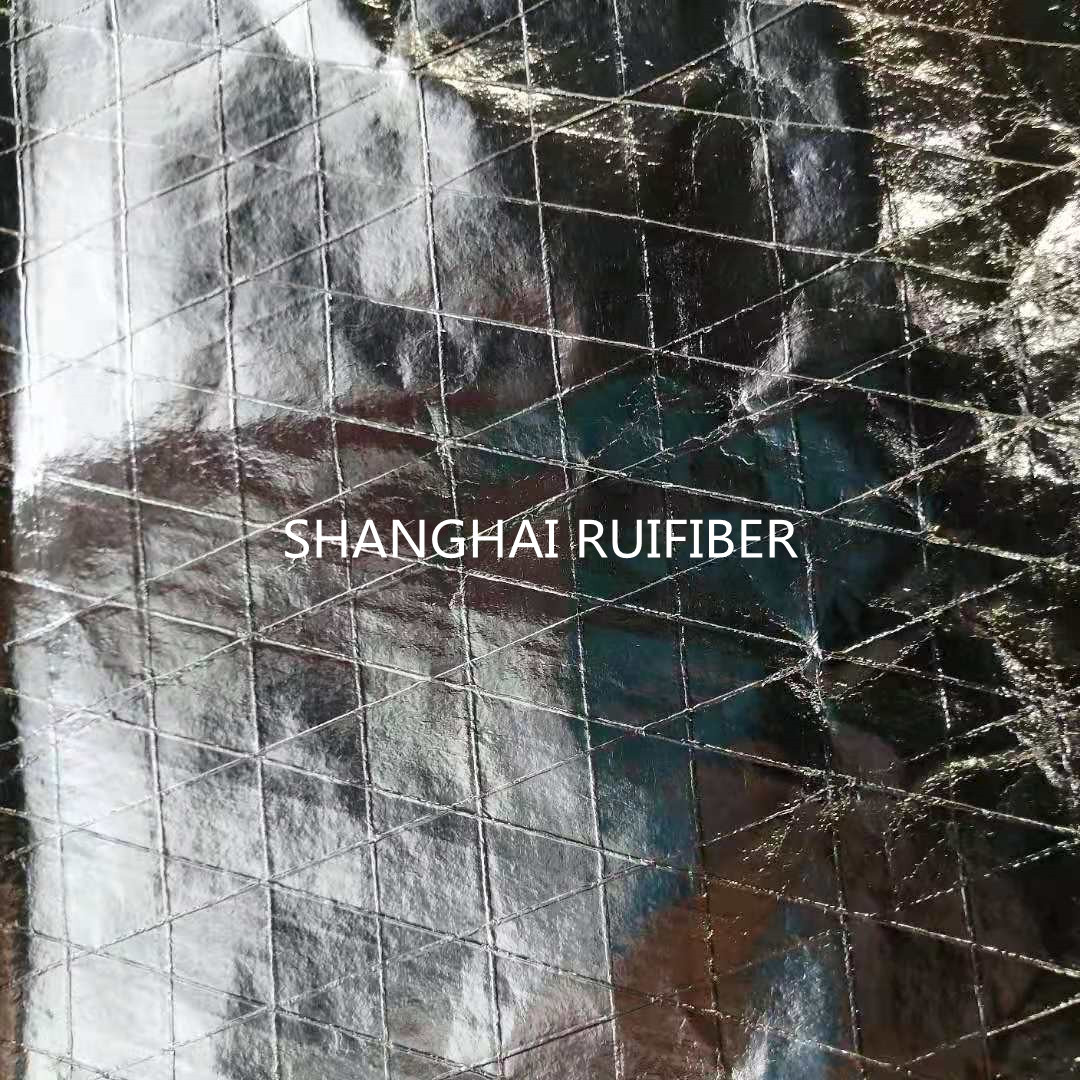

Laid scrim is widely applied in a aluminum foil industry. It can help manufacture to develop the production efficiency as the roll length can reach 10000m. It also makes the finished product with better appearance.

Non-woven laid scrim is widely applied in aluminium foil industry. It can help manufacture to develop the production efficiency as the roll length can reach 10000m. It also makes the finished product with better appearance. Other usages: Textile roofing and roofing shields, Insulation and insulating material, Intermediate layer for vapor permeable underlay, air and vapor barriers (Alu and PE films), Transfer tapes and Foam tapes.

GRP pipe fabrication

Double yarn non woven laid scrim is an ideal choice for pipe maufacturers. The pipeline with laid scrim has good uniformity and expansibility, cold resistance, high temperature resistance and crack resistance, which can greatly extend the service life of the pipeline.

Packaging

Laid scrim mainly used for producing Foam tape composite, Double sided tape compound & Lamination of masking tape. Envelopes, Cardboard containers, Transport boxes, Anticorrosive paper, Air bubble cushioning, Paper bags with windows, high transparent films can us also.

None-woven category products reinforced

Laid scrim is widely used as reinforced materail on kinds none-woven fabric, such as fiberglass tissue, polyester mat, wipes, Antistatic textiles, Pocket filter, filtration, Needle punched non-wovens, Cable wrapping, Tissues, also some top ends, such as medical paper. It can makes none-woven products with higher tensile strength,while just add very little unit weight.

Flooring

Now all major domestic and foreign manufactures are applying laid scrim as the reinforcement layer to avoiding the joint or bulge between pieces, which is caused by the heat expansion and contraction of materials.

Other usages: PVC flooring/PVC, Carpet, Carpet tiles, Ceramic, wood or glass mosaic tiles, Mosaic parquet(underside bonding), Indoor and outdoor, tracks for sports and playgrounds.

PVC Tarpaulin

Laid scrim can be used as basic materials to produce truck cover, light awning, banner, sail cloth etc.

Triaxial laid scrims also can be used for producing Sail laminates, Table tennis rackets, Kiteboards, Sandwich technology of skis and snowboards.Increase the strength and tensile strength of the finished product.

Laid scrim is cost-effective! Highly automatic machinery production, low raw material consumption, less labor input. Compare to traditional mesh, laid scrims have a great advantage in price!

Welcome to visit Shanghai Ruifiber, offices and work plants, at your earliest convenience.——www.rfiber-laidscrim.com