Laminated sailcloth with scrim-HOW STRETCHY AND STRONG IT IS?

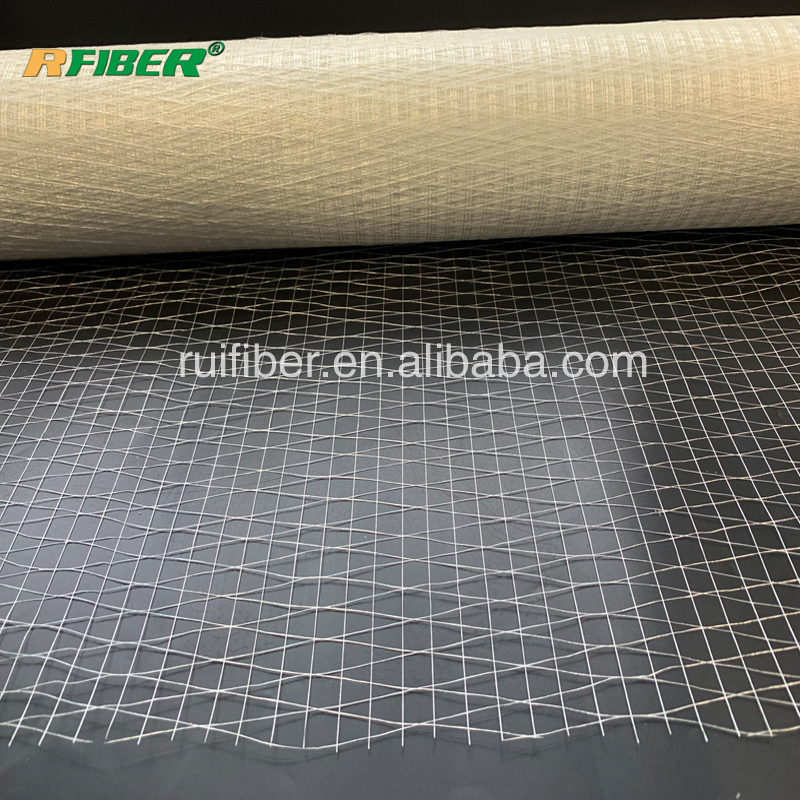

A laid scrim looks like a grid or lattice. It is a cost-effective reinforcing fabric made from continuous filament yarn in an open mesh construction. The laid scrim manufacturing process chemically bonds non-woven yarns together, enhancing the scrim with unique characteristics.

High tenacity, Flexible, Tensile strength, Low shrinkage, Low elongation, Fire-proof Flame retardant,Waterproof,Corrosionresistant,Heat-sealable,Self-adhesive,Epoxy-resin friendly, Decomposable, Recyclable etc.

Laid scrim can be used as basic materials to produce truck cover, light awning, banner, sail cloth etc.

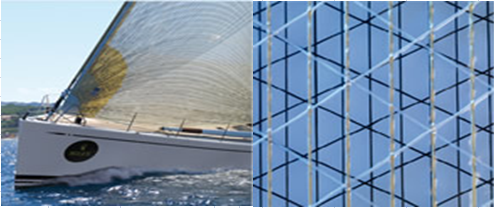

Triaxial laid scrims also can be used for producing Sail laminates, Table tennis rackets, Kite boards, Sandwich technology of skis and snowboards. Increase the strength and tensile strength of the finished product.

Sails made from these laminates were stronger and faster than conventional, densely woven sails. It is partly due to the smoother surface of the new sails, which results in lower aerodynamic resistance and better airflow, as well as to the fact that such sails are lighter and because of that faster than woven sails. Still, to achieve maximum sail performance and win a race, stability of the initially designed aerodynamic sail shape is also required. In order to investigate how stable new sails can be under different wind conditions, we performed numerous tensile tests on different modern, laminated sailcloth. The paper presented here describes how stretchy and strong new sails really are.

Polyester (PET)

The most common type of polyester, is the most common fiber used in sailcloth; it is also commonly referred to by the brand name Dacron. PET has excellent resiliency, high abrasion resistance, high UV resistance, high flex strength and low cost. Low absorbency allows the fiber to dry quickly. PET has been replaced by stronger fibers for most serious racing applications, but remains the most popular sail cloth due to lower price and high durability. Dacron is the brand name of Dupont’s Type 52 high modulus fiber made specifically for sailcloth. Allied Signal has produced a fiber called 1W70 polyester that has a 27% higher tenacity than Dacron. Other trade names include Terylene, Tetoron, Trevira and Diolen.

PET

PET film is the most common film used in laminated sailcloth. It is an extruded and biaxially oriented version of PET fiber. In the US and Britain, the most well-known trade names are Mylar and Melinex.

Laminated sailcloth

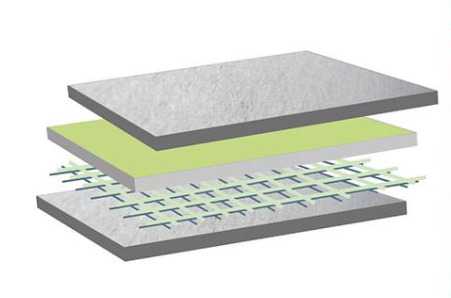

In the 1970s sailmakers began to laminate multiple materials with different characteristics to synergize the qualities of each. Using sheets of PET or PEN reduces stretch in all directions, where weaves are most efficient in the direction of the threadlines. Lamination also allow fibers to be placed in a straight, uninterrupted paths. There are four main construction styles:

Film-scrim-film or film-insert-film (film-on-film)

In this construction, a scrim or strands (inserts) are sandwiched between layers of film. Thus load-bearing members are laid straight, which maximizes the high modulus of the fibers, where a woven material will have some inherent stretch to the weave. Laminating film to film around the strands creates a very strong and dependable bond reducing the amount of adhesive needed. In high quality cloth, the strands or scrim are tensioned during the lamination process.

The drawbacks are: film is not as abrasion or flex resistant as a weave, it does not protect the structural fibers from UV rays. In some cases UV protection is added.

Welcome to visit Shanghai Ruifiber, offices and work plants, at your earliest convenience.——www.rfiber-laidscrim.com