Materials used in pipelines 1 – Reinforcing, Insulating, and Waterproofing Solutions!

Introduction: In the dynamic pipeline industry, the choice of materials plays a crucial role in ensuring the operational efficiency, longevity, and safety of pipeline systems. At our esteemed company, we offer a comprehensive range of high-quality materials specifically designed for pipeline applications. From laid scrim and polyester netting to PET film, BOPP film, fiberglass roving, chopped strand mat, fiberglass mesh, fiberglass tissue, reinforced non-woven fabric, spunbond non-woven fabric, spunlace non-woven fabric, and chemical bond non-woven fabric, our products excel in providing enhanced reinforcement, insulation, and waterproofing capabilities. Read on to discover the essential features, applications, advantages, and unique properties of each material.

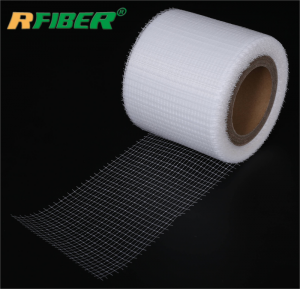

Laid Scrim/Polyester Netting:

- Describe the features and advantages of laid scrim/polyester netting, such as its unique grid size and width, and the advanced manufacturing processes employed to produce this reinforcement material.

- Highlight its applications in enhancing the structural integrity and durability of pipelines, providing added protection against potential damages and ensuring long-term reliability.

- Emphasize the customizable options we offer, including various widths, lengths, and grid sizes, allowing customers to tailor the material to their specific pipeline requirements.

- Mention the reliable domestic supply that ensures prompt delivery to clients in the Middle East, Asia, North America, Europe, and other regions.

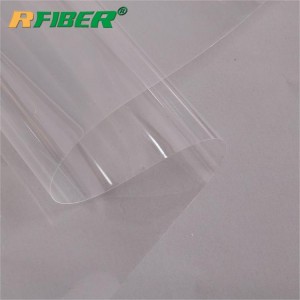

- Highlight the properties of PET film, such as its excellent tensile strength, chemical resistance, and dimensional stability.

- Explain its role in providing barrier protection against moisture, gases, and chemicals, thus safeguarding pipeline systems from potential damage.

- Discuss its application in pipeline insulation to minimize heat loss, maximize energy efficiency, and ensure consistent temperature control.

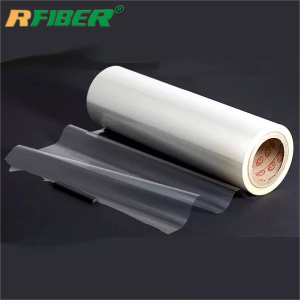

BOPP Film:

- Describe the unique advantages of BOPP film, including its high clarity, excellent tensile strength, moisture resistance, and low permeability.

- Explain how BOPP film acts as a barrier, preventing water, chemicals, and other external elements from penetrating pipelines and causing corrosion or contamination.

- Highlight its use in pipeline wrapping and electrical insulation applications, ensuring long-lasting performance and safety.

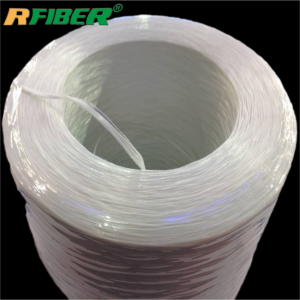

- Discuss the superior strength and flexibility of fiberglass roving, making it an ideal material for reinforcing pipeline structures.

- Explain how fiberglass roving improves the rigidity and resistance of pipelines to external forces and environmental conditions.

- Introduce its use in enhancing the load-bearing capacity and durability of pipelines, ensuring optimal performance and mitigating the risk of failure.