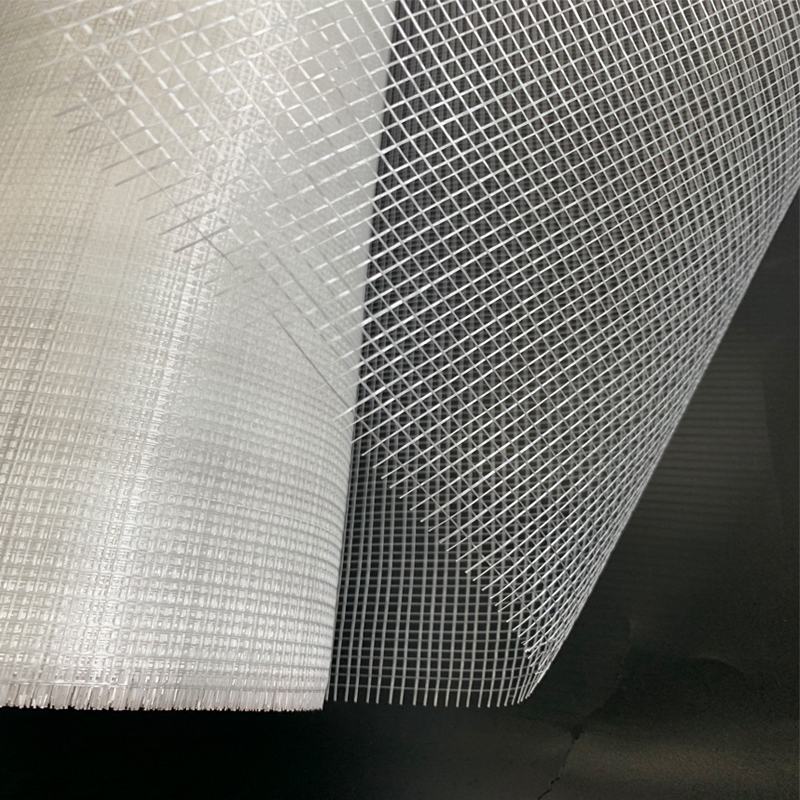

Tarpaulin with Scrim Reinforcement

A polyethylene tarpaulin is not a traditional fabric, but rather, a laminate of woven and sheet material. The center is loosely woven from strips of polyethylene plastic, with sheets of the same material bonded to the surface. This creates a fabric-like material that resists stretching well in all directions and is waterproof. Sheets can be either of low density polyethylene or high density polyethylene. When treated against ultraviolet light, these tarpaulins can last for years exposed to the elements, but non-UV treated material will quickly become brittle and lose strength and water resistance if exposed to sunlight.

Industrial tarpaulin shade is used in the industries for protecting the industrial raw-materials and finished goods of the industries from weather & moisture to protect them from rust & corrosion. They also aid in carrying our industrial work process by shading the workshops.

Laid scrims are exactly what we say: weft yarns are simply laid across a bottom warp sheet, then trapped with a top warp sheet. The whole structure is then coated with an adhesive to bond the warp and weft sheets together creating a robust construction. This is achieved through a manufacturing process, which was developed in house, that allows manufacture of wide width scrims at widths up to 5.2m, at high speed and excellent quality. The process is typically 10 to 15 times faster than the production rate of an equivalent woven scrim.

At Shanghai Ruifiber, we take pride in our dedicated technical experience with woven, laid, and laminated textiles. It’s our job to work closely with our customers on a variety of new projects not only as suppliers, but as developers. This involves getting to know you and your project needs inside and out, so that we can dedicate ourselves to creating the ideal solution for you.